Once you’ve finished counting inventory at your dealership, there is still important work to be done. That’s because your inventory count should have revealed what your slow-moving parts are and what items you can safely label as “dead inventory” or “dead stock.”

If your dealership has dead inventory on its hands, you’re wasting hundreds and potentially thousands of dollars that could have been used towards something else.

We’ve previously collaborated with industry experts who gave their insights for our Guide on Organizing Your Inventory for Profitability, which can be downloaded at the bottom of this blog. Using those insights, we’ll explain everything you need to know about dead inventory, including what to do with it and how to avoid it.

The information in this blog post will also help you figure out a realistic plan of action for your dealership’s dead inventory and how to organize new inventory to maximize your cash flow.

Table of Contents

- What is Dead Inventory AKA Dead Stock?

- Why is Dead Inventory a Problem?

- What Should You Do with Dead Stock?

- How Do You Avoid Dead Inventory?

- How Should You Organize Inventory & New Stock?

- Guide on Organizing Your Inventory for Profitability

What is Dead Inventory AKA Dead Stock?

Dead inventory is also known as “dead stock” or “obsolete inventory.” Dead stock or dead inventory are unsold items that are unlikely to sell in the future.

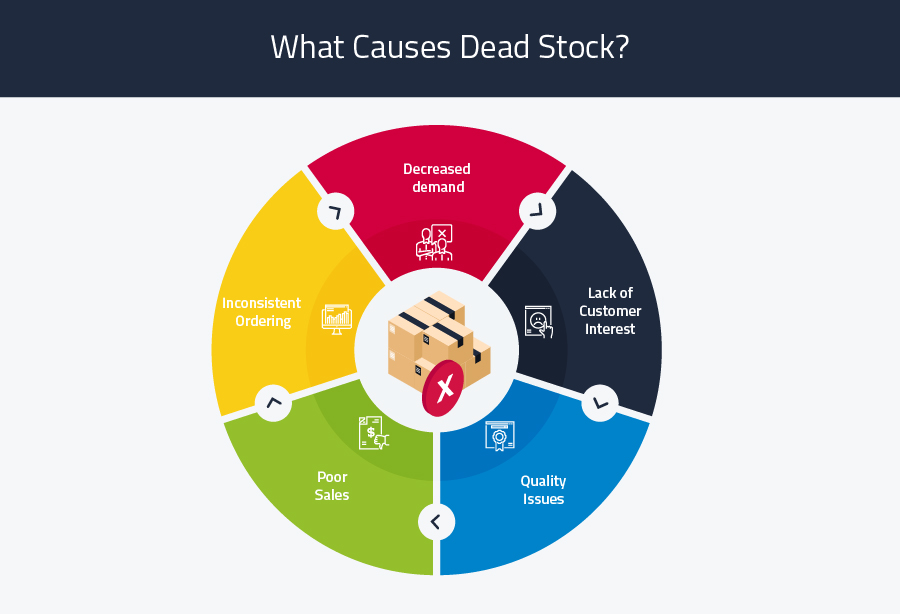

The most common reasons for dead inventory:

There are several reasons for dead stock. One of the most common reasons is decreased demand for an item. Decreased demand can come on suddenly because of factors outside of your control, such as the COVID-19 pandemic or economic circumstances. A lack of customer interest in an item over time also causes dead stock.

Quality issues can also influence a customer’s lack of interest. Quality issues include defects with a product or if a customer’s expectations about a product are not fulfilled. If customers are not satisfied with their experience, it can cause poor sales and ultimately dead inventory.

Avoid inconsistent ordering of inventory:

Lastly, dead stock can also happen because of inconsistent ordering practices, like buying the item at the wrong time. For example, in anticipation of holiday shopping, buying too much of a certain product could leave you with dead stock if only half is sold. The opposite is also true. If you re-order a product too late, you could miss out on the holiday shopping season entirely and end up with dead stock in the new year.

Pay attention to seasonal trends:

On this note, it’s important to be aware of seasonal trends as well. A decent dealership management system will be able to help you keep track of your inventory, not just for the whole year but in anticipation of seasonal purchasing trends too.

Notice the interconnectedness of each factor and just how easy it is for dead inventory to build up over time if you are not properly taking count of it.

Read Next: Dealership Inventory Counting Tips – Getting the Count Right

Why is Dead Inventory a Problem?

Clearly, dead inventory can become a significant problem for your business if you let it. Still, it’s helpful to put into perspective why it’s a problem. Identifying the problems will help you come up with the solutions needed to minimize dead inventory at your dealership and remove some of the guesswork from inventory planning.

- Money Lost

Inventory purchases are a business investment. Items that sell help recuperate that investment and turn a profit. However, you can lose your investment if you have dead inventory. At the very least, it minimizes your chance to break even.

- Less Inventory Space

Not only does having dead stock cost you money, but it occupies space that could have been used by a faster-moving product. The longer it takes up space, the more your business stands to lose because you need to continue paying for rent, utilities, and other costs at your dealership.

- Sunk Cost Fallacy

Holding on to dead stock may also prevent you from ordering new parts because you might be hoping that the item will sell in the future. You might also be hesitant to get rid of it because of the costs you’ve already incurred such as time, money, or resources. This is an example of the sunk cost fallacy. The sunk cost fallacy may be tempting to fall into, but it will lead you astray and cause you to make poor decisions you might not have made otherwise.

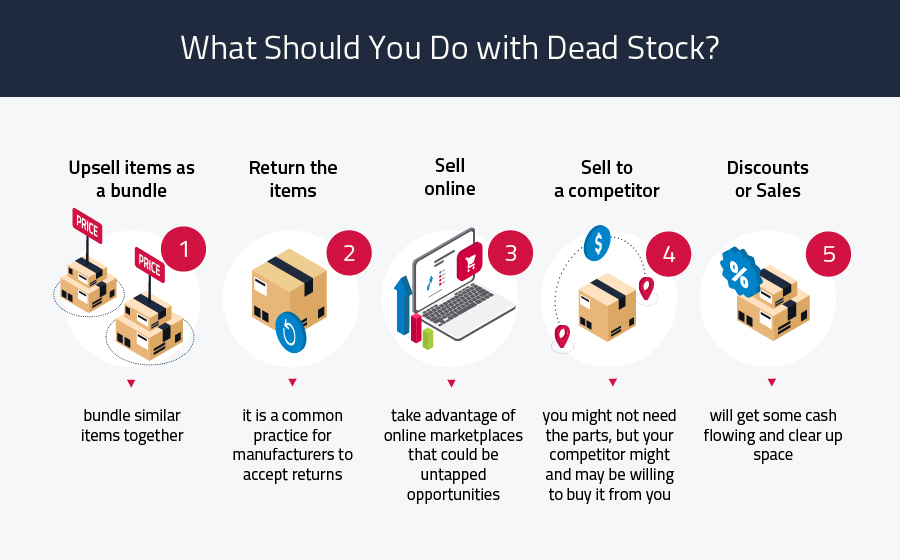

What Should You Do with Dead Stock?

So, you’ve identified the items in your inventory that are dead. Now what? Not to worry – there are plenty of options available.

- Upsell the items as a bundle

For bundling to work, items need to be related to each other, so customers won’t feel like the bundle is being forced on them or doesn’t properly address their needs. By bundling a slow-moving item with one that is fast-moving or bundling similar products together, you can offload stock at a lower price than if customers bought the items separately.

- Return the items

It’s common practice for manufacturers to accept returned parts at least once a year. They may take some parts back and offer you a percentage of their cost or store credit. Take advantage of that opportunity and set up policies ahead of time that will handle this process.

- Sell online

Just because your current parts aren’t selling for your business, it doesn’t mean that another business or independent buyer won’t take them. Try using online marketplaces, such as eBay, Amazon, and even the Facebook marketplace.

- Sell to a competitor

As counterintuitive as it sounds, selling to a competitor lets you be compensated for your items, especially if they might be needed somewhere else. Although your business might not need the item, your competitor might need it instead, depending on their own inventory needs.

- Discounts or sales

While you won’t get a 100% return on your items for selling them at a discount, it will clear up space in your inventory and get cash flowing.

Read Next: 5 e-Commerce Dealership Best Practices Customers Expect

How Do You Avoid Dead Inventory?

While there are ways to eliminate dead stock, the best practice is to avoid having it altogether. Here are a few ways that you can avoid dead inventory. It begins with having the right data at your disposal.

- Use a Dealership Management Software

An industry-specific dealer management system should have features for parts and inventory management to run reports that tell you exactly what parts are selling the most and the least. It also keeps better track of your inventory levels because you have up-to-date information about your inventory.

- Set MIN and MAX ordering levels

This is another feature that a decent DMS should have so that when your current supply of an item reaches a minimum level, the system knows automatically to place an order and ensure that it doesn’t exceed the maximum amount. Setting MIN and MAX levels can also be set on a seasonal basis.

- Speed up the ordering process

Electronic Data Interchange will automatically exchange important business information with your supplier to ensure the timely arrival of inventory and accurate pricing. This will also help reduce human error. Having the right information and data is crucial to avoiding dead inventory.

Read Next: How Lansdowne-Moody Uses Data Reporting to Beat the Competition

How Should You Organize Inventory & New Stock?

Before you even think of adding new parts to your inventory, make sure you understand what you currently have and what you need. It’s important that your gut feeling does not drive your new purchase decisions. Make your decisions based on tangible information obtained from things such as customer feedback, sales results, or your DMS. Ensure that you have a good organization system in place so that the inventory area can accommodate new products.

Here’s how you can organize your space.

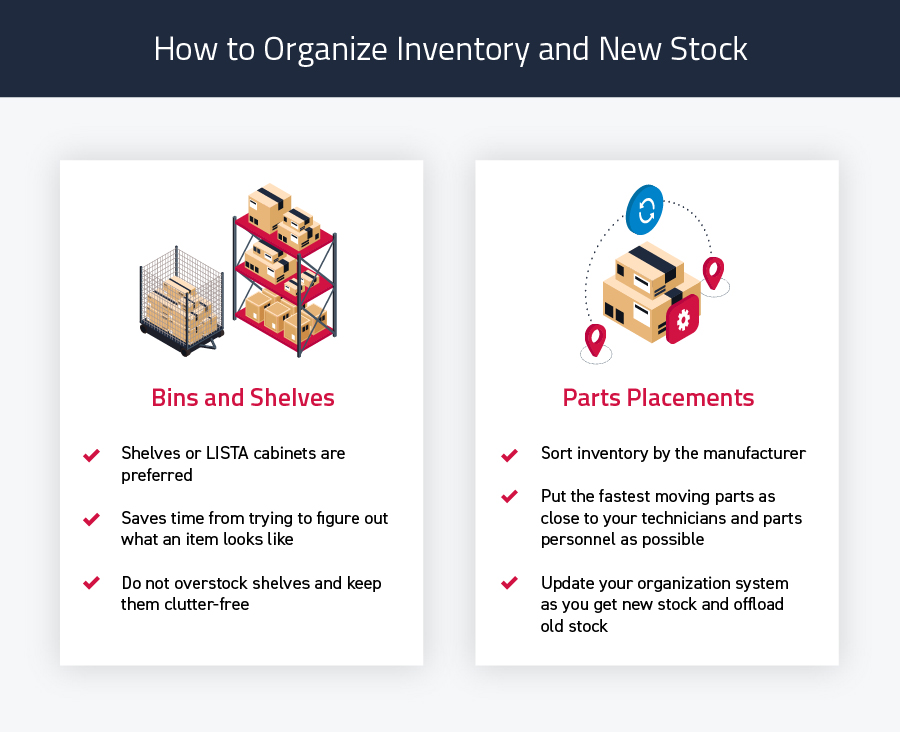

Bins and Shelves

Your bin locations should be set up so that all the parts are exactly where you need them. Shelves or LISTA cabinets are preferable because parts can be organized by location. For example, spark plugs are in Unit A, Shelf 1, Position A. When you’re looking for a specific part, you just need to identify its location. This saves you time from having to figure out what it looks like.

Similarly, it is important not to over-stock the shelves either and ensure that they’re as clutter-free as possible. This gives you the flexibility to easily rearrange parts when needed. Although it will take some to set up the bins, it will help your parts and service department move more quickly and efficiently.

Parts Placement

Look at how your dealership currently organizes its parts. If your parts are arranged by vendor and vendor type, then it’s probably not organized in the best way. Instead, sort inventory by the manufacturer.

Why you shouldn’t sort by vendor:

Sorting by vendor can be problematic because part numbers change over time. This causes your fastest-moving items to end up in the back. It will take up more of your technicians’ time when they go looking for parts, reducing your dealership’s service productivity.

Where to put your fastest-moving parts:

The exception is to put the fastest moving parts as close as possible to your technicians and parts personnel. It’s also a good practice that if you go through certain kits on a regular basis, you group them together.

You can determine what new items are needed and where to put them once you’ve got a proper organization system.

Keep your parts organization up to date

Over time, you will identify the need for new parts in your inventory and which items to get rid of. It is important to keep your organization method as up-to-date as possible and update it if needed. There is always more that can be done to maximize your dealership’s inventory management and to prevent dead stock from overwhelming your business operations.

Download the Guide

To learn more, click on the image below to get our Guide on Organizing Your Inventory for Profitability.

![Fixed Absorption: Your Dealership’s Recession Shield [Infographic]](https://www.discorp.com/wp-content/uploads/2025/04/Blog-prev-190x190.jpg)